Monumental hands for the Temple of Together at Burning Man

The Temple at Burning Man has always been special. For those that don't know about it, a quick story: at the Burning Man festival it's become a tradition to build a temple, a non-denominational space for remembrance of those recently lost, celebration, and worship in your own way. A sort of architectural competition, artists submit their ideas for it, and the winning design gets built by a large crew of volunteers working hard to bring it to life (and raise the money to help pay for it all!).

During the festival people leave memorial notes and objects in it, people get married in it, various services are held in it, and then the day after the Man burns the Temple is burned too. When the Man burns, it's a huge raucous party; when the Temple burns, it's totally somber, with many thousands of people watching in respectful silence. It's quite powerful.

Since it's volunteer built, and many of the same people volunteer year after year to help, a Temple Builder's Guild has grown to help bring the winning idea to life. I helped with the temple back in 2011 and 2013, and decided to get involved again this year. The initial design called for a pair of monumental hands out in front. The team needed help making these real, which was something right up my alley to be able to help with.

Image from the Temple of Together website

As we were reviewing the timeline, budget, and ease of constructability (and burnability!) of the design, we eventually decided together as a team to go with a more faceted design that could be quickly produced from CNC-cut flat panels of plywood. While we loved the form of the final design, making smooth curved forms would have taken more time, and thinner plywood or other options for skinning them quickly could become a hazard when burned due to them flying off more easily in the wind. So the hands were remodeled to a final faceted form for the hand and front, with a lattice on the backside to match the temple's outer walls.

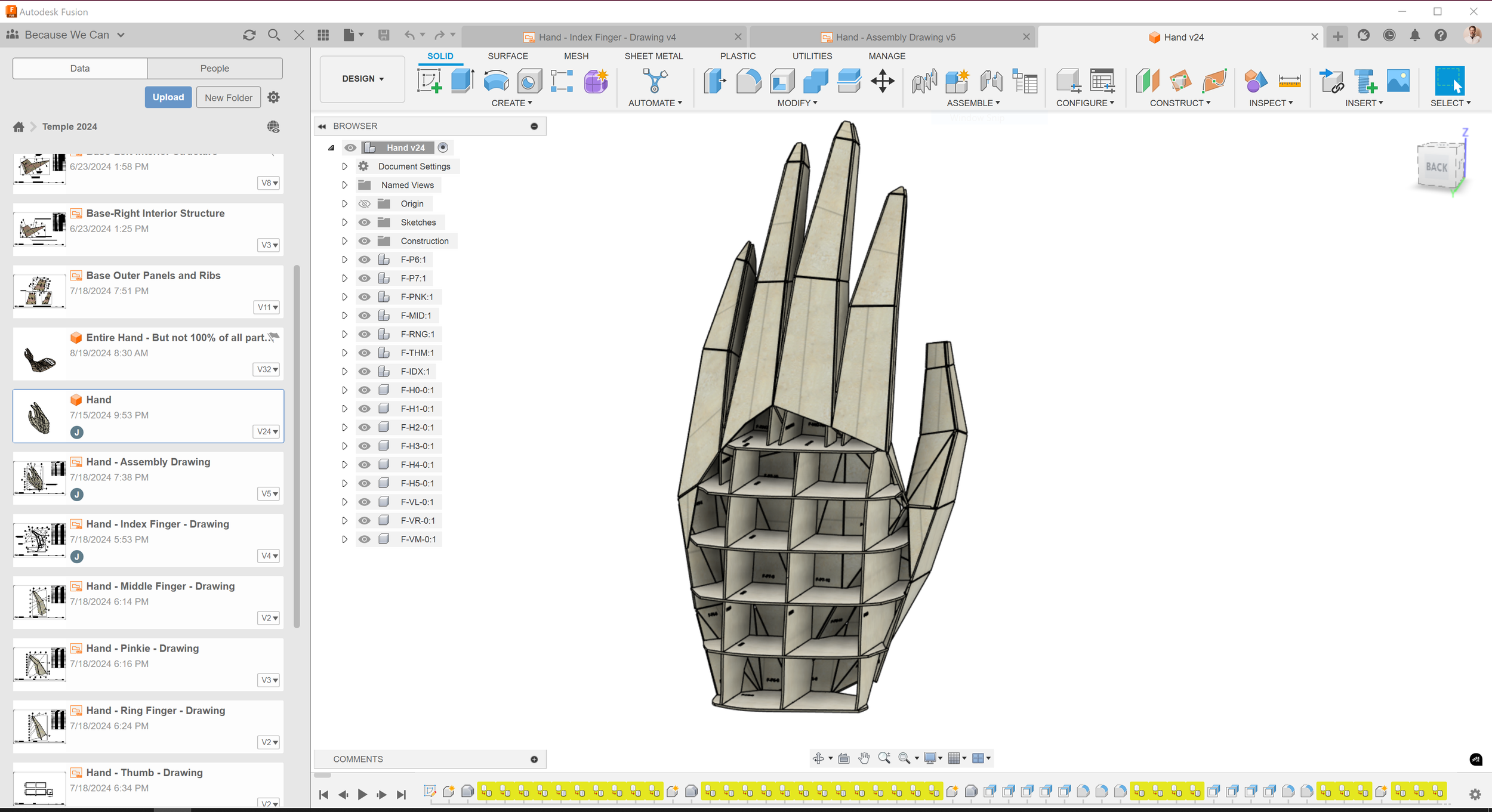

Next step was to make it real, and for that I used Autodesk Fusion. While Blender is awesome, it's not really a CAD platform, and since most of the hands were going to be made from CNC-cut plywood I wanted to use a tool best suited for quickly making manufacture-ready models. So I imported the mesh from Blender, turned the mesh into a solid using T-splines, and then got to work on the internal structures.

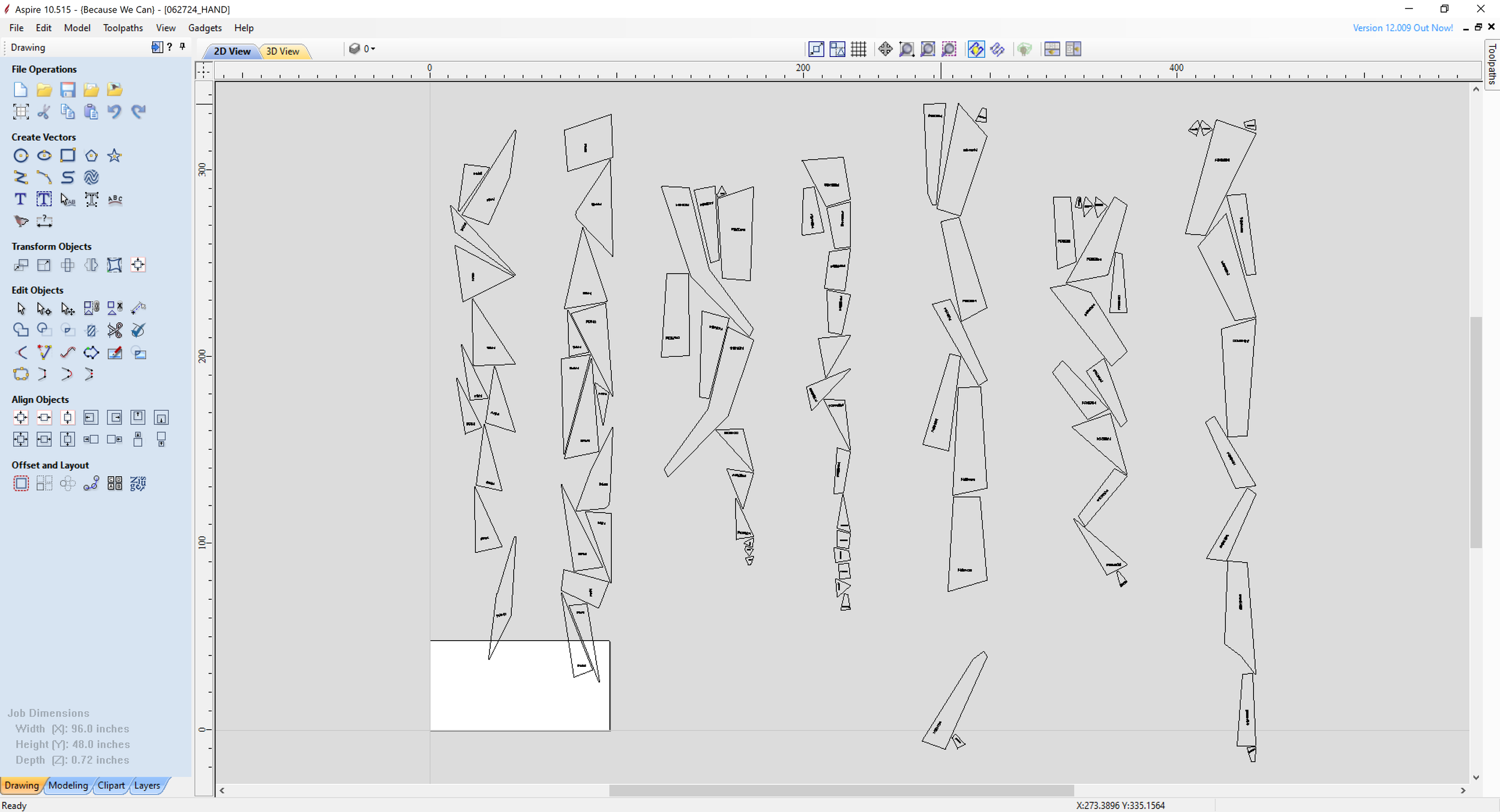

Fusion enables me to do simple FEA calculations so I know my designs are plausible and structurally sound, and the parametric solid modeling tools made pretty quick work of all the complex profiles required to 'flat pack' parts of the hands. Then once all the parts and panels were figured out, everything was exported to flat DXFs for various different shops to cut the parts on CNC routers. It also allowed for the team to participate collaboratively online together, to where non-CAD using volunteers helping with the build could review the latest models directly from a web browser. Since I too am just a volunteer, and don't have a lot of extra time, it was critical for me to use tools that empowered me to do the most work in the least amount of time, and to automate as much as possible.

A lot of thought was put into trying to make this complex build as easy as possible, as it's being done mostly using volunteers of various skill levels. We used a numbering system to help label every single one of the hundreds of parts and help direct where that part was supposed to go within the overall structure. We also aimed to make many of the parts not require CNC production, as that can become a major bottleneck with a project that has a large pool of manual labor volunteers but only a few CNC machines available to it. So many parts were designed in a way that they could be produced either by CNC or with just a track saw and some careful measurements. And the overall design had to be very forgiving for tolerances, so it could use whatever donated materials and volunteer labor were available. Finally while it was going to be largely preassembled, it had to be made into several large logically chunks that could both fit onto a flatbed truck, get safely lifted into place, and quickly connected together, as the build team only has a few weeks to put the entire temple together once they get to the playa.

Another thing that was a huge time saver for me was Fusion's newish semi-automated shop drawing tools, where it would largely make all the shop drawings not only for the assemblies, but for every part too.

The final hand structures were 35’ tall, fully freestanding (they don’t touch!), and really looked great along with an overall stunning temple.

Image from Rand Larson of Morningstar Productions

And last night it was all burned to the ground, turned to ash and dust.

Thanks again to the Temple Builder's Guild for being a great group to work with. Honored to have been included in this awesome project and we’re looking forward to next year!