AUTODESK DESIGN & MAKE AWARD

【CLIENT】

AUTODESK

【PLACE + TIME】

Las Vegas, NV / 2023 & 2024

【PROJECT SCOPE】

Designing an award that appeals to the engineers, construction experts and designers on the receiving end. Using multiple materials, digital fabrication the piece needs to have a use outside of being just an award…. 32 count.

【PROJECT TEAM】

Because We Can ✦ Design Concepts, Renderings, Prototypes, Final Fabrication

The Autodesk 2023 Design & Make Award “celebrate(s) the people, projects and technologies behind exceptional contributions to architecture, engineering & construction; product design & manufacturing; media & entertainment; and education.”

Presented at Autodesk University every year, this high profile award is an important part of the event, and as such the company (Autodesk) wanted it to be special. Coming out of the pandemic, the team at Autodesk heard an overall desire from award receivers to not just another paper weight award that sits untouched on a shelf. That is where we came in, with the unique challenge to create a mass producible object that has function, delight, the proper aesthetic, and spoke to the exceptional people who would be the receivers.

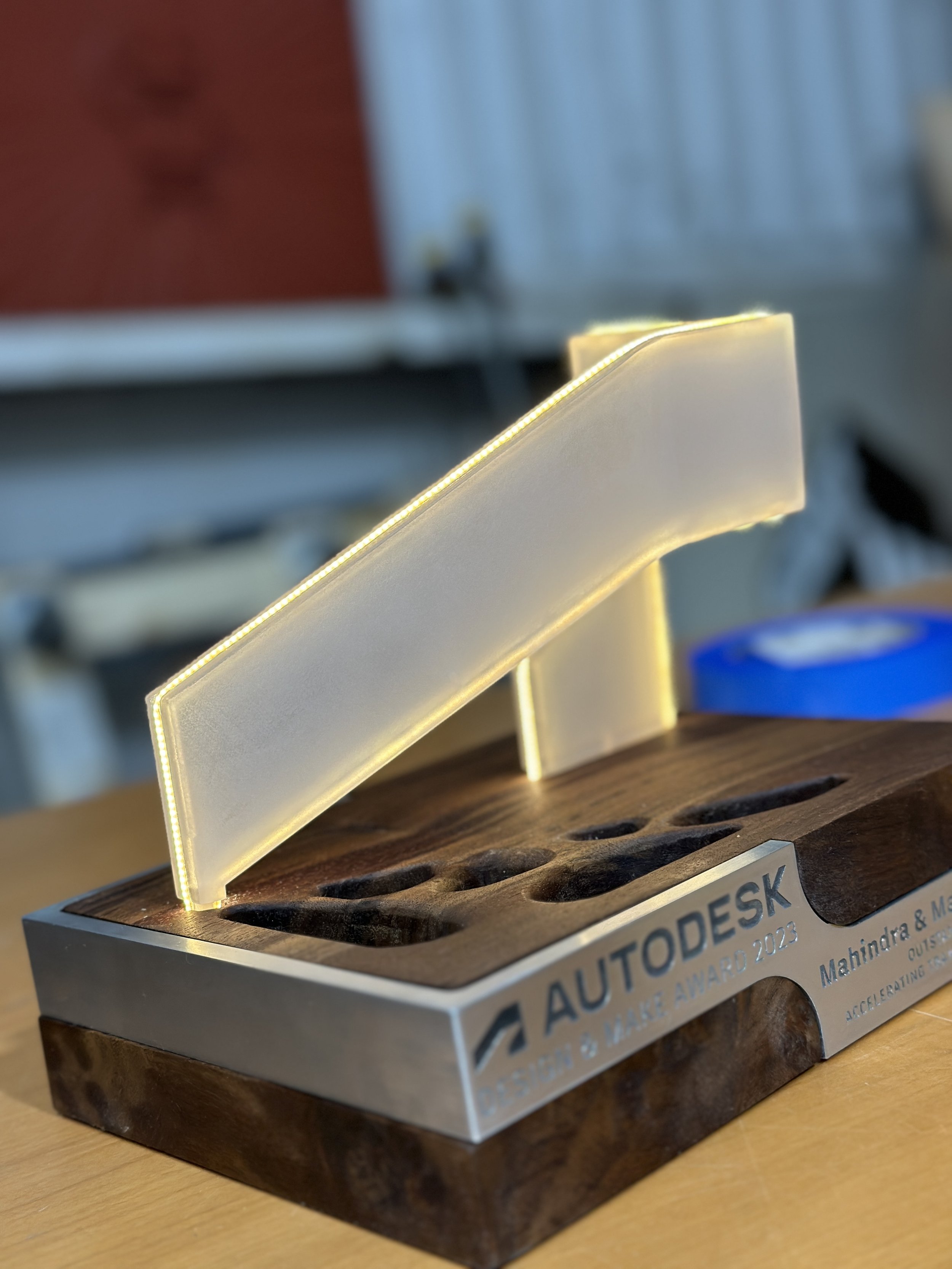

We worked closely with the Autodesk team, rising to this design challenge. In the end we designed 32 individual awards that each have a light with a switch, an induction charger & a secret drawer for special objects. The combination of hand craftsmanship and digital manufacturing in the final piece add a wonderful level of interest.

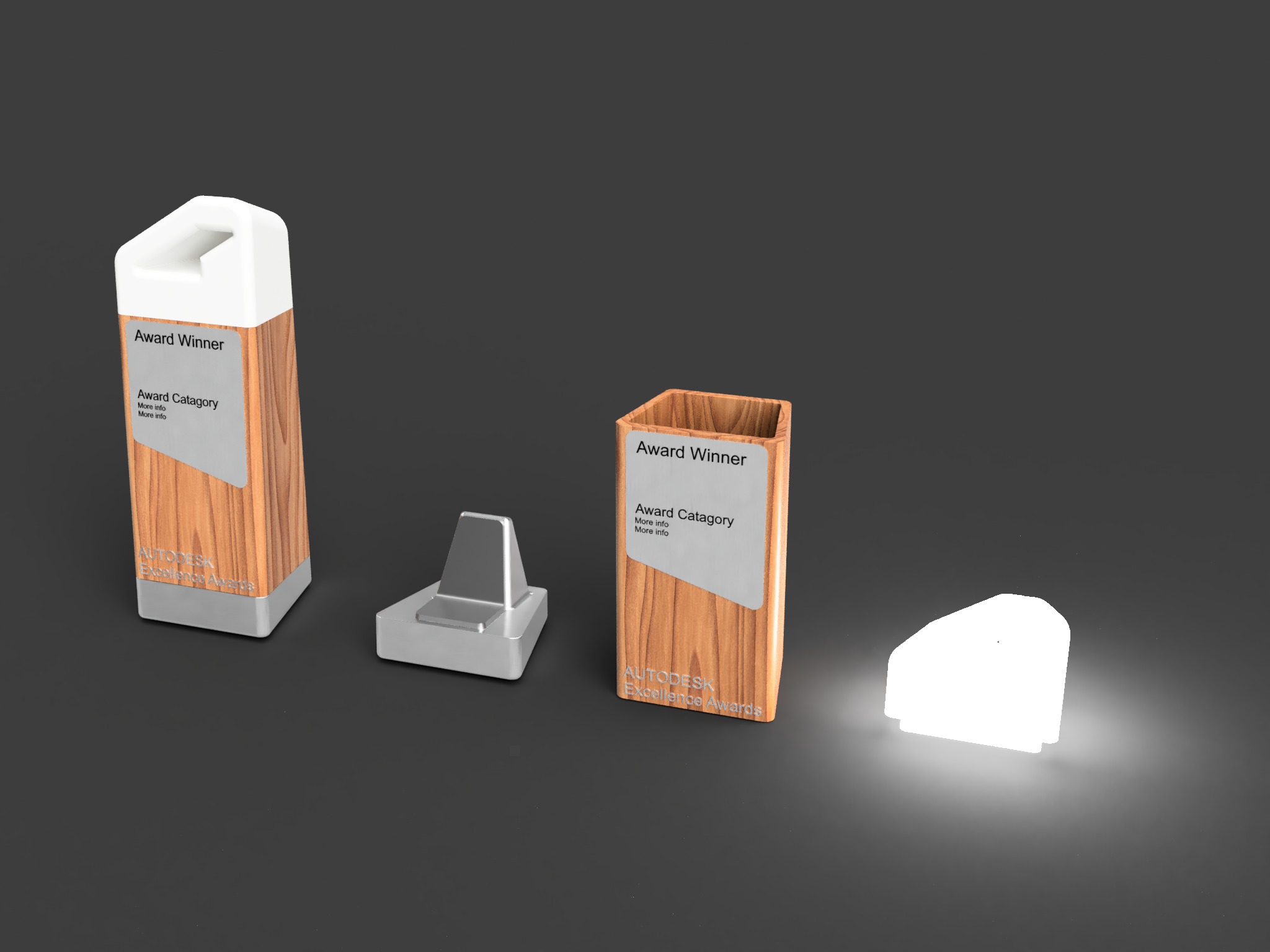

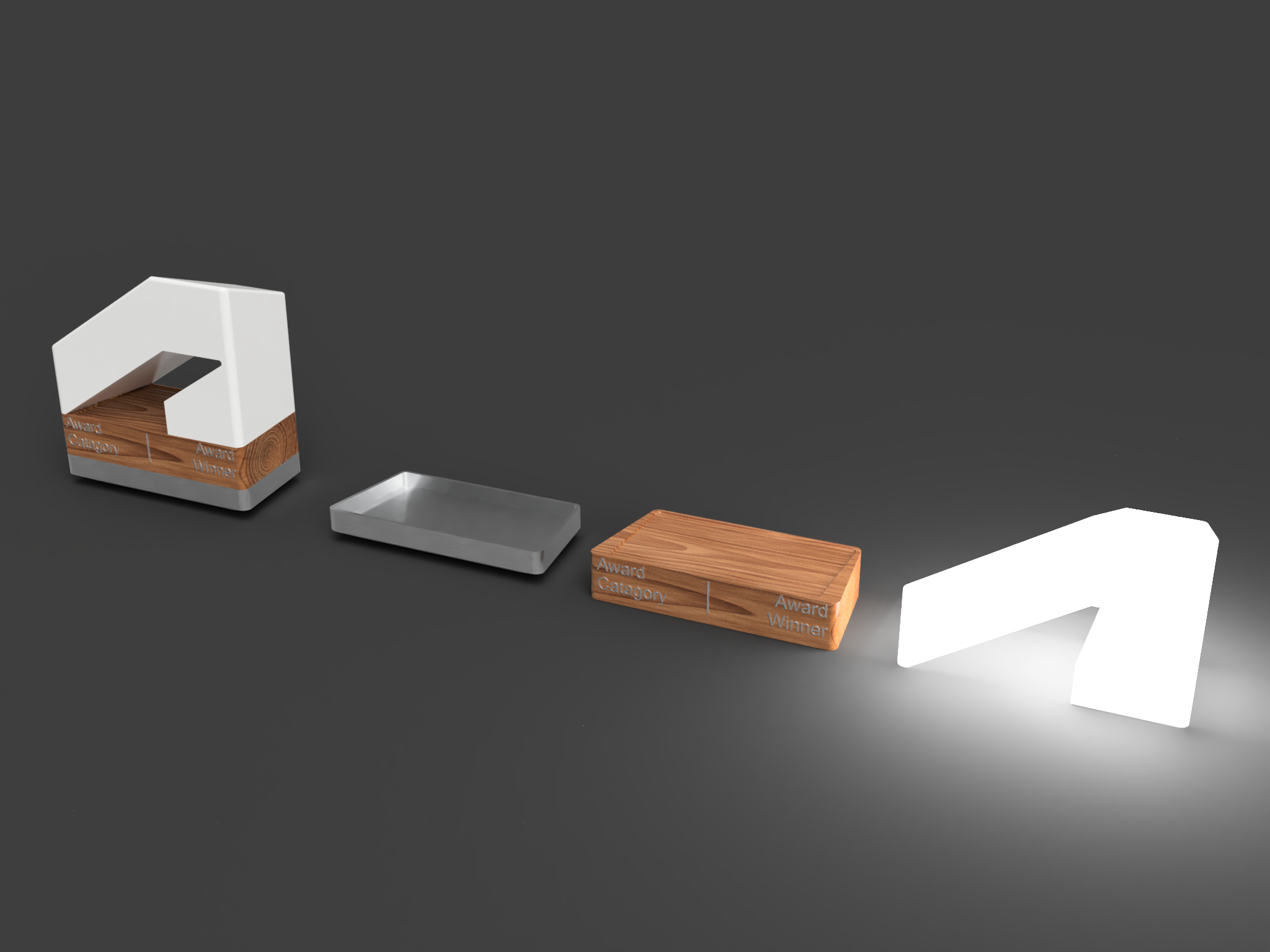

We entered the design process in a typical fashion, presenting to the client several different directions the award could go. By this point in the design process we had already defined the desire for a light, and induction charger and a vessel of some kind. It was now time to define the shape.

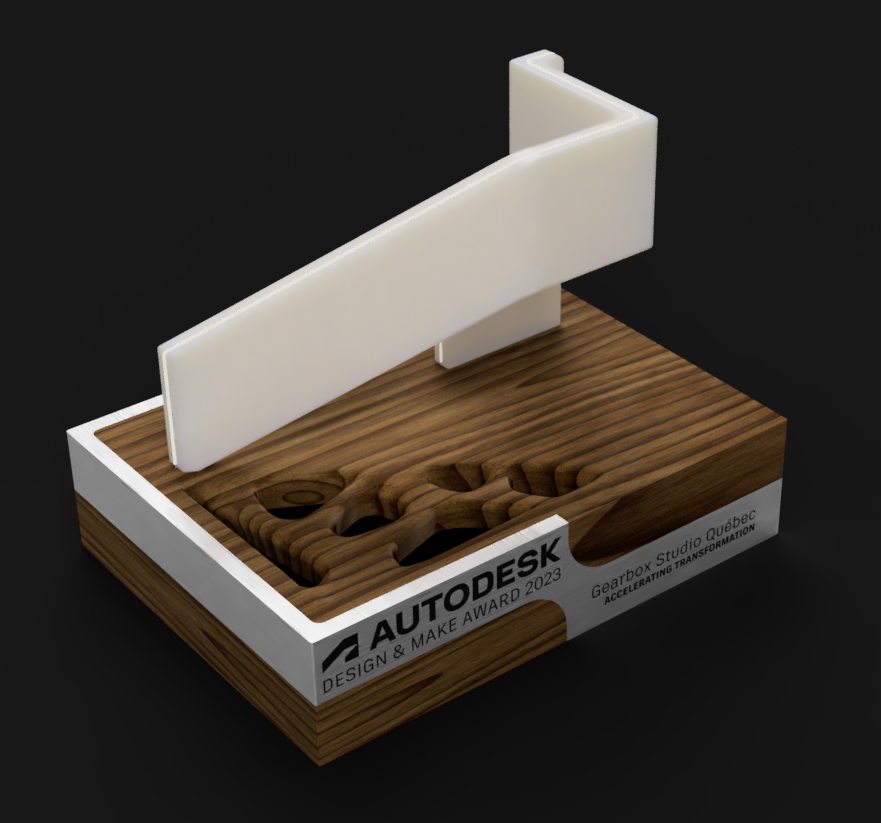

Landing on a strong logo presence for the award, Autodesk chose to have the logo on the top be the main focal point with a plinth base to hold the electronics and secret drawer. We refied the design, creating a clean aesthetic that matched with the company’s current branding design.

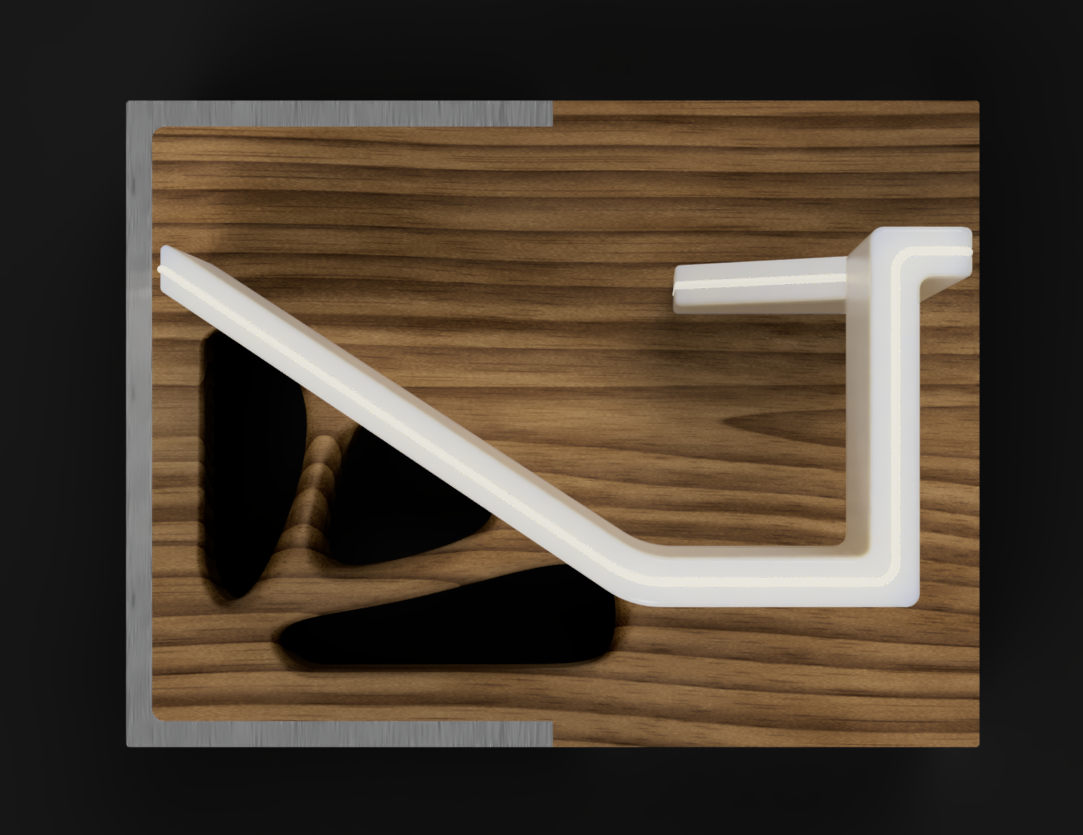

The shape and materials defined, we were off to the production of these 32 individually named awards. We hand selected salvaged walnut planks from our local area for the base and used recyclable aluminum for the chassis core. The walnut planks were carved at our in house production shop with our 5 Axises CNC machine, and then topped with a 3D printed logo, which we imbedded with the LED light string.

The salvaged walnut was sourced nearby from a farm in Petaluma. The hardwood is highly figured, a deep rich color and each slab hand picked for its unique beauty, adding an individuality to each custom award. This wood is a bit more difficult to work with, but worth it for its striking appearance. Paired with the materials of the brushed aluminum and soft glow of the sanded 3D print, the clean but rich aesthetic comes together.

Every element was designed by out in house team and hand assembled in our production shop. This making of video shows the level of detail and all the components that went into the final custom awards.

Autodesk Design Make Award-2023 the making of…