Disclaimer

This series is purely for informational and educational purposes and does not constitute professional or legal advice. While this information is provided by Because We Can, and while we endeavor to keep this information up to date and correct, we make no representations or warranties of any kind, express or implied, as to the accuracy or completeness of this information. We do not provide any guarantees or warrant and do not accept any liability on your actions from this information. Any reliance you place on such information is therefore strictly at your own risk, and we highly recommend you hire a building professional (like us) to review your specific case.

Applications, Plans, and Variances

Oh my! In this section we’ll dig into all the different sorts of applications, documents, and paperwork you’ll typically need to submit to legally build a project.

Applications

Most things you’re going to build are going to need some sort of approval from a building official before you start. Usually this approval is formally asked for and granted with some sort of application of a specific form for the type of work you’re doing, which when approved grants you a permit for that work. These forms are filled out with the relevant project information, and usually involve submitting more information along with it, such as photos, plans, calculations, reports, and more.

A very simple project, such as minor electrical work, reroofing a house, putting in a new heating system to replace an old one, replacing cabinets in a kitchen, etc. might not need anything more than a written description of the work on the application form itself, and can even be approved over the counter.

A more complex project, such as remodeling a warehouse into a condo complex, will require not only more information than just a written description, they will typically need multiple applications, documents, and approvals from many different City agencies that will need to spend time reviewing all the information extensively. These various applications are going to need specific and complete information about your project, organized in the way that City likes, in order for them to get approval. Ask questions, follow the directions exactly that are on the forms, and make sure to complete them fully.

Typically all of the approved applications are collectively called the ‘building permit’. Your project was reviewed by the different City building officials, usually starting with Planning, then Building, and then sometimes onto Fire and even local municipal utilities, and each department reviewed and formally approved things, with the final step being the City issuing you a building permit. For certain types of projects, there could even be a public review before the city officials review it at all, where the project will go before a planning board or a city counsel, and they and/or the general public be allowed to make comments on the project before it moves forward.

Usually the ‘building permit’ actually takes the form of a special sort of checklist you’ll keep onsite at the project, with the official set of all the plans, forms, and other documents along with it that the City officially approved. Various building inspectors will then write comments and sign off things on that special checklist (sometimes called a ‘job card’) as they are built, inspected, and approved.

There can also be different applications and approvals for different phases and even parts of a project. For example, you could just apply to the Planning department with a scheme of what ‘could be’ done, that once approved, becomes something called an ‘entitlement’ that adds value to the property. For now you’ve got legal ‘proof’ that the City would let you build that sort of a building on that site. So a legal pre-approval for a big house on an empty lot or tearing down a defunct commercial property to build an apartment building. This reduces risk to a developer, for now they don’t have to do that legwork, and already have planning approval in hand for when they go for the actual building permit to build the actual building, even if it’s not exactly the same as the building that was submitted for the entitlement.

There can be ‘sub-applications’ too, where you’ll need to file applications for various approvals within a specific department, such as when dealing with a historic building that might require additional review and approval from a specific person or team within the larger planning department. Or having to apply for operational permits from the health department before you can properly start using your new restaurant’s kitchen.

Once you do get the building permit, you might have to get additional approvals to put a construction dumpster out front of the building, file paperwork showing how you’re meeting City-required recycling goals, keep records on how you’re meeting OSHA requirements during construction, permits to temporarily close the parking out front to make room for the concrete truck on the day of the concrete pour, and more.

And as the project is close to completion, you may want to apply for a ‘Temporary Certificate of Occupancy’ or ‘TCO’ that would let you start to move in and use the building, even though it’s still technically ‘under construction’ as the contractors are wrapping things up. And once the project is complete, you’ll need to ‘close out’ the permit by ensuring everything on that checklist has been signed off that needs it and that the official Certificate of Occupancy has been updated and more.

The thing is the approved applications, and the various drawings and documents within, usually become legal documents that go on file within the City. They impact the property values and insurance terms for the building, become the legal basis for what you can use a building for, would become really important in any lawsuit about the building, and more. So being well-organized, keeping good notes and records, and making copies of everything will go a long way here.

It’s a lot of leg work and a lot of paperwork, and one of the areas that hiring someone experienced in the specific process for the kind of project you’re doing can be a huge help. There is a reason that people can make whole careers out of just helping get complex projects through a larger city’s various departments! But thankfully if you can’t afford to hire skilled help in this area I’ve found that if you’re friendly, nice, respectful, and ask lots of questions the different building officials will help point you in the right directions of what applications and approvals you’ll need to make for your project. Even us professionals in this space have to do this to properly navigate these waters!

Plans (& Specifications, calcs, reports, photos…)

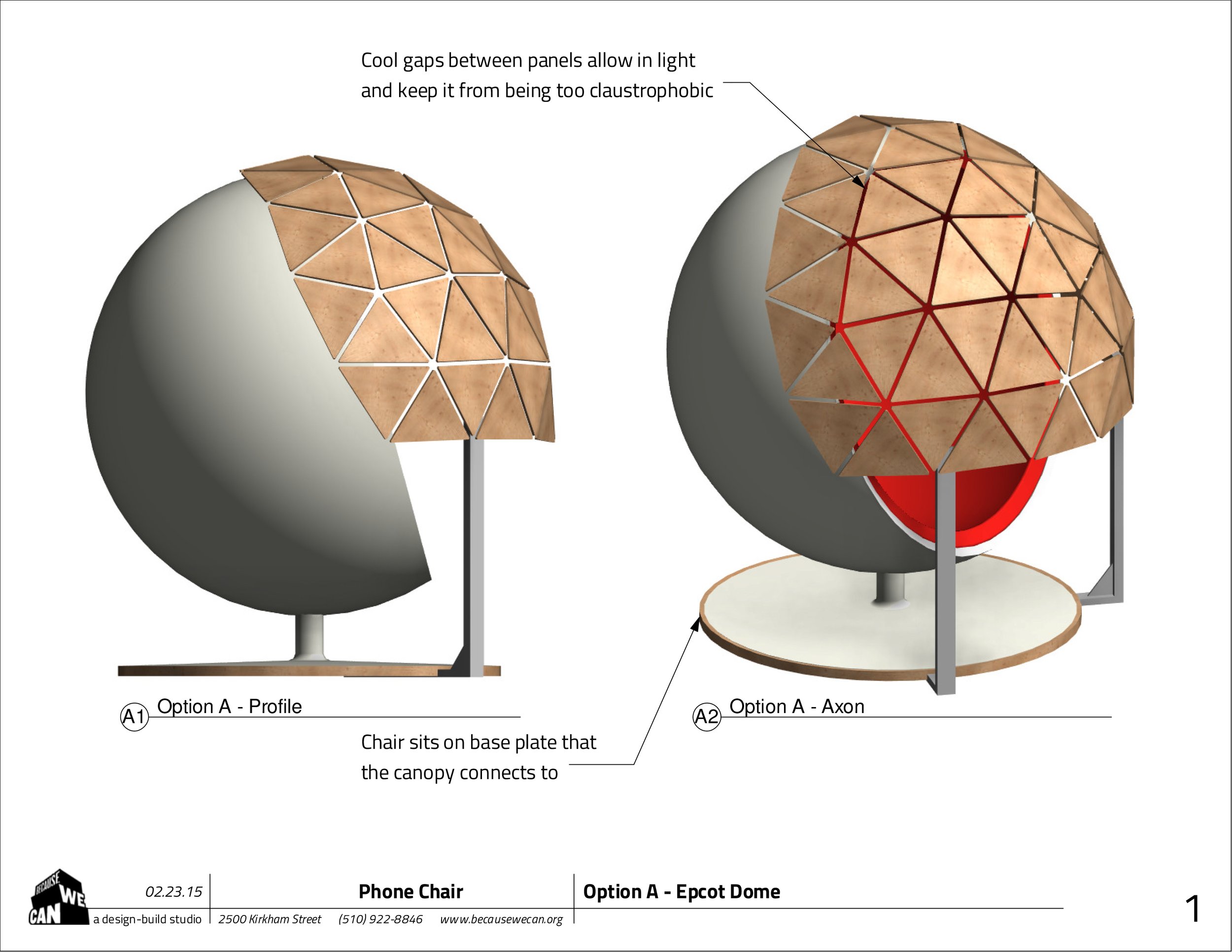

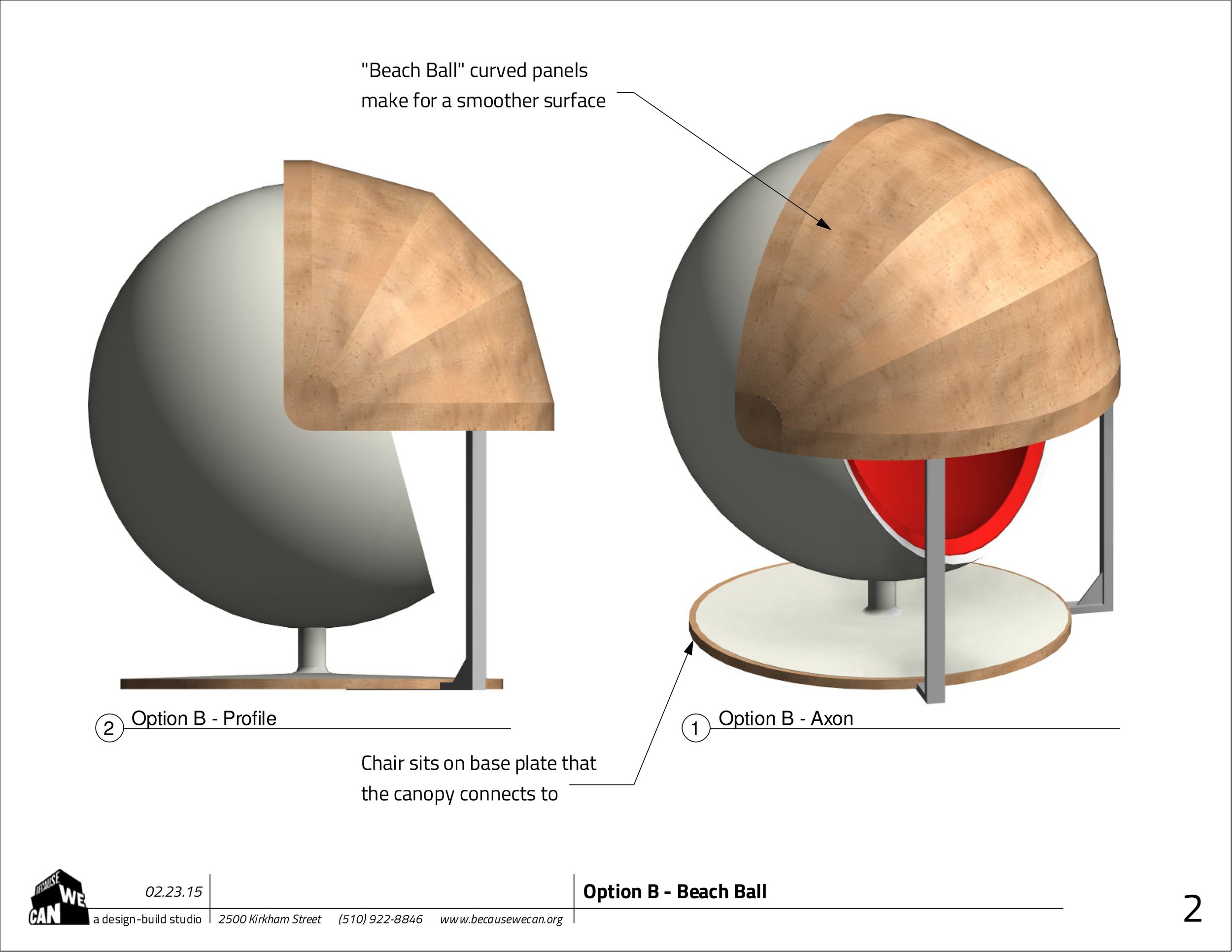

From a simple sketch to a stack of drawings a foot high, Plans are one of the main vehicles for defining, organizing, communicating, and documenting your project.

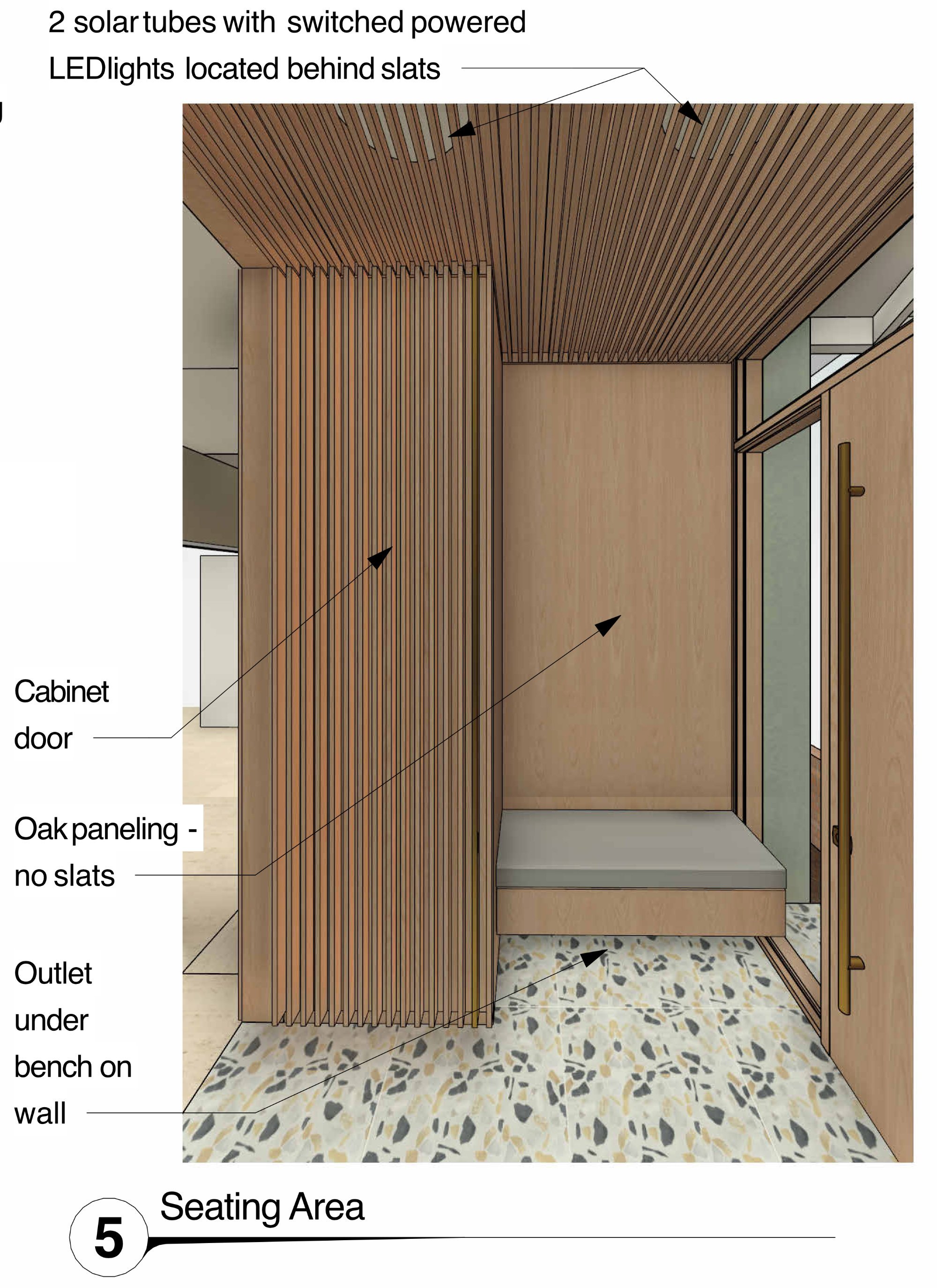

There are a few different standards people follow when creating plans, and thankfully most Cities will have some sort of guide or checklist of how they like plans prepared and what needs to be in them as a minimum. But generally a ‘set of plans’ will:

Start with title pages that usually have a list of the sheets in the set, the project location, basic project description, what standards the project will follow, and copies of various forms required for the permit.

Then have site plans pointing out where the work is to happen exactly, what the surrounding area / buildings are, what the overall plot of land is, and what changes are being done to it.

Then have various floor and ceiling plans showing what’s existing, what’s getting removed, and what’s getting built.

Then elevations showing the outside of the building & walls, again showing what’s existing, what’s getting removed, and what’s getting built.

Then sections (cutaway views), detailed drawings of specific bits of the building, enlarged plans of specific spots within the building, schedules and more towards the end that show all the nitty-gritty details of how the building is going to be built, and how it’s going to meet the various Codes it has to.

The plans usually just show how the building is going to be built, what’s going to be done, etc. Sometimes projects will also require ‘specifications’ which is a written document that outlines in more detail what specific materials, brands, and vendors can be used for the different elements within the building, and usually will also outline the approved ways those materials will be used or installed. Things like directing for the bathroom tile to be one of three brands, for the mortar used to install it be a specific type, for the tile to be stored onsite in a safe way, and for the boxes of tile to be opened and mixed together to ensure a consistent color is all the sort of things that go into a good ‘spec’ as it’s sometimes called.

Sometimes projects will also require things like structural calculations, environmental impact reports, site photos, and more things that aren’t ‘plans’ in the traditional ‘blueprint drawing’ sense, but will need to be included and kept together with the plans, and are considered part of the ‘set of plans’.

These sets of plans become legal documents, in that when you submit them to the City and get them approved, that is now the legal record for what you’re planning to build. If what you actually build doesn’t match, the building inspectors won’t approve it, even if what you did was fully to code. Hence why as the project changes, the plans need to be changed, and resubmitted for approval. Typically this will be called an ‘Addendum’ or a ‘Revision’, and sometimes if the change is big enough, it will even get a new building permit altogether. While sadly some architects don’t keep these plans up to date, it’s actually part of their professional responsibility and standards to do so, and to always have a reasonably up to date, fully coordinated set of plans for the project as it progresses. This is easy for Architects using BIM in a smart way (like we do) and much harder for those who aren’t, so it’s a good question to ask whomever you are hiring if they are working fully and correctly in BIM vs. 2D CAD or even still on paper.

Most plans are required to be prepared by a properly licensed architect and/or engineer. Commercial projects, anything involving redoing structure, etc. have to be prepared by a professional, who will ‘sign and stamp’ those drawings. When they do so, they are legally taking on the liability for what’s in those plans, and whatever issues may arise when it’s built. It may seem unfair or some sort of ‘professional capture’ forcing you to hire someone like me, but it’s honestly a kind of a deal around public safety. Architects and Engineers legally only get to do this sort of work (and call themselves by these titles) in return for being on the hook for whatever they propose in those plans.

For example, if your uncle tells you that you can totally pull out that pillar that’s in the way of your kitchen remodel, and you do so, and it causes part of your house to expensively fail, it’s pretty much on you. You can try to sue your uncle who gave you bad advice, but legally it’s entirely your responsibility and fault for doing structural work without an architect or engineer looking at it first.

If an architect or engineer makes a bad mistake like that, they are on the hook, and it’s legally their fault, not yours, and it’s a pretty straightforward case to make them fix the problems they caused (and your homeowner’s or business insurance company won’t be mad at you). That’s the deal, it’s exactly like a lawyer or doctor, only they get to do certain types of work and call themselves that, but in return they are liable and responsible for that work.

However, some smaller houses and residential remodels can be drawn up by anyone, hence why your kitchen designer can do all the drawings for your kitchen remodel. And as we said in the approvals section above, some really simple projects don’t even need drawings, just written descriptions, and can have over-the-counter permits.

Variances

A ‘Variance’ is when you get official written approval to either not have to follow a specific rule in the code, or replace one rule with another. These also have to typically be applied for, and approved by the building officials, and honestly can be quite hard to get in many cases. You have to have a really good reason for it, and usually have to do something more strict in ‘trade’ to get one.

For example, let’s say you have an existing building that was built a long time ago, and the planning rules have changed, and now your building has windows that are too close to the property lines to meet code. It may be possible to work out with the City that you’ll add in much more fireproofing around those windows, replace the windows with highly fire-rated ones, and add in a fire sprinkler system, and once you’ve documented how you’re going to do all of that, the City could grant you a variance that for this one specific project, and this one time, just this once, you’re going to be allowed to keep those windows because you’re doing above-and-beyond what’s normally needed.

So while variances are possible, they are unlikely and hard to get, so don’t be the future of your project on them until you have them in hand.

Applications get you approvals (and usually require plans), approvals get you permits, permits allow you to legally build things.

Next up in our final installment in this series we’ll dive into Inspections and Inspectors, how things tend to happen during the project, and project close-outs. I hope you’ve been finding this series helpful and as always I love to talk about these things, so please reach out to me if you have questions!